Nutrition Database for Food Labelling

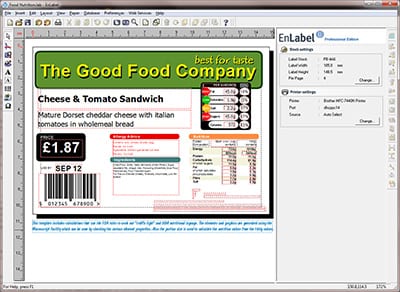

Here at Positive ID we are developing a nutrition database for food labelling for our customers. The system has now been completed and is marketed as NutriData.

A nutrition database for food labelling is required for any food manufacturer selling prepacked food for sale to the public. There are criteria that must be met for your company to be classed as needing to include nutrition data on your food. You can find out more from the government’s website.

The regulations stipulating the need for nutrition information on food labels has been around since 2013. The EU FIC regulations have had a five-year implementation period, coming into full force in December 2016. Recognising this and the large numbers of small food businesses we supply labels to, we identified the need to help.

Nutrition data is freely available by downloading the government accepted nutrition database provide by McCance & Widdowson. This data set can be used to calculate nutrition data for foods but is cumbersome to say the least.

Positive ID Labelling employed a software developer to help us provide a fully working solution – available for use across the EU. It is ironic that our software developer was from Greece, taking advantage of the free movement of people across the EU and something PID has benefited from.

The software means the nutrition database for food labelling is accessible and can be used to compile nutrition information for consumers. Users compile a local database of ingredients. The nutrition data for the ingredients can be input manually from the packaging of the ingredient or imported from the McCance & Widdowson database that is included with the software.

Users then compile the ingredients into recipes. The recipe includes the quantities of each ingredient. Cross-referencing the ingredients with their nutrition data allows a recipe to be amalgamated into a nutrition table for that recipe.

Once the recipe is completed, it can be cut down (if it is a large batch made into smaller servings) and can be adjusted for cooking. Cook loss effectively concentrates the nutrition values into a smaller weight, increasing the nutrient density of the uncooked product.

Once the recipe stage is complete, the user compiles the recipe into products, including standard statements on storage, warnings, best before or use by perishability.

The software automatically calculates percentages of each ingredient in the recipe and orders them largest to smallest in keeping with Quantitative Ingredient Declaration requirements (QUID).

The finished product(s) can then be exported to an Excel spreadsheet where they can be used with most labelling software programs. Just click here and pop over to our sister website to learn more about the Nutridata software.

Alternatively, call us on 01332 864895 or fill in the form and we will get back to you.

Advanced encryption keeps your data safe and secure

Advanced encryption keeps your data safe and secure