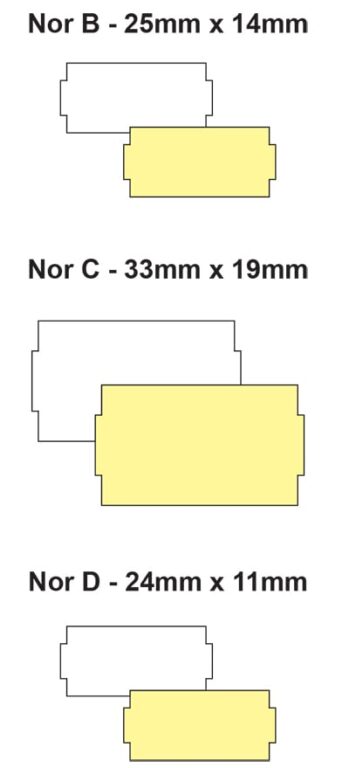

We can offer labels in a range of sizes and carry many common sizes of plain (white) in stock for next day delivery. We can provide labels in colour washed format (any colour you want really) and fully pre-printed for use on your products.

Direct Thermal Printer Labels

Thermal printer labels come in two material types – direct thermal and thermal transfer. Direct thermal labels have an invisible pigment printed on the surface of the material. This pigment reacts to heat in the thermal print head of the thermal label printer and turns black. Direct Thermal labels are suitable for use for up to 6 months. They are commonly used in sandwich labelling or short shelf-life products and in courier labelling.

Thermal Transfer Printer Labels

Thermal transfer printer labels have no pigment and will not print without the use of a printer ribbon. Printer ribbons need to be suited to the material being used. Thermal Transfer labels are often either vellum (plain paper), a coated paper known as semi-gloss or polypropylene – a plastic. Wax ribbons will give the lowest or most economical finish. Wax/resin mixed ribbons will give a better finish. Resin ribbons give the highest performance. Resin ribbons are required to print on plastic materials as wax will not delaminate and adhere to plastics.

Plain Label Production

We make these with ease and very economically on our plain label converters. We have three Daco Solutions plain label converters. One is a Daco PLD350 which 350mm wide (13.75 inch) web width converter. This can take master rolls of 6,000 metres of feedstock. We also have two Daco PLD250 which are 250mm (10 inch) wide converters that can accept up to 2,000 metres of feedstock. They are all capable of running at over 130 metres per minute to produce plain labels for thermal printing purposes.

All three are fitted with turret rewinders and can produce labels on 76mm cores, 44mm cores, 38mm cores or 25mm cores. Larger cores are suited to industrial thermal label printers whereas 38mm and 25mm cores are suited to small desktop printers.

We are happy to produce small runs of as few as 10,000 labels all the way up to millions of labels per order.

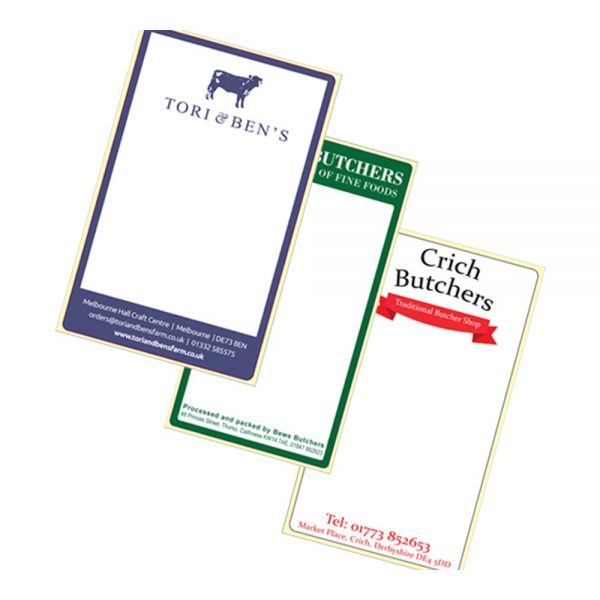

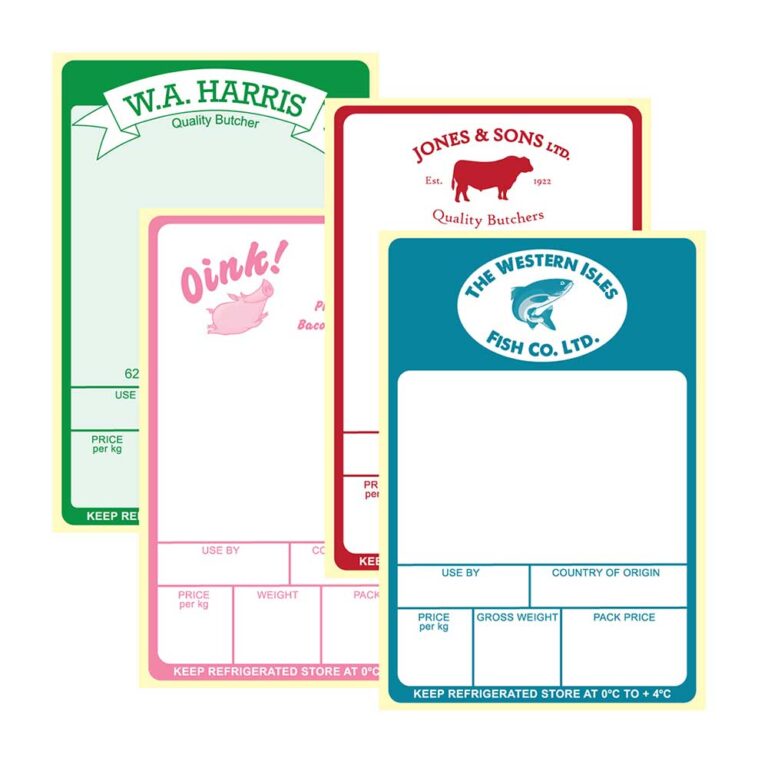

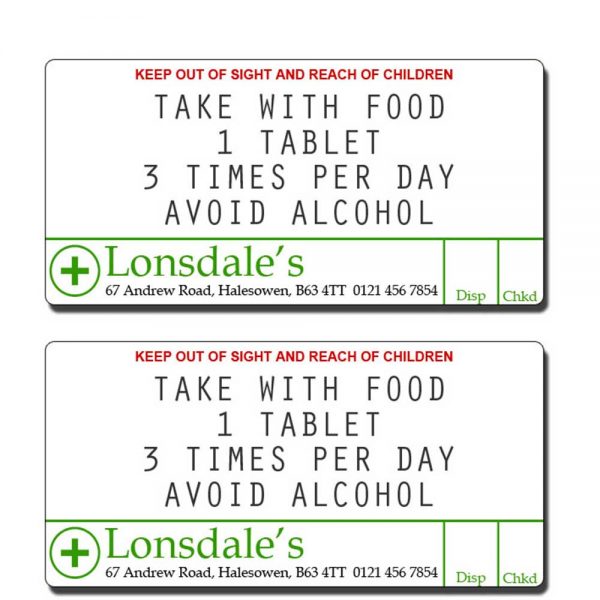

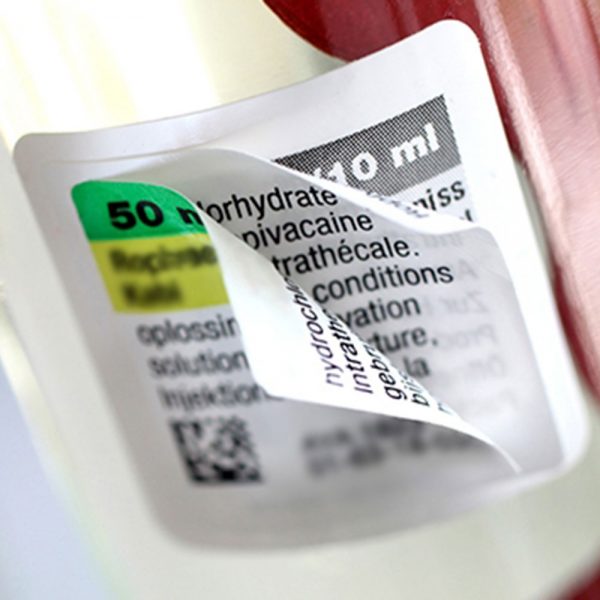

Printed Thermal Printer Labels

Ideally suited to food or chemical use, we can pre-print thermal printer labels using any of our printing presses. This includes our flexographic MPS-350, Edale Alpha 250 and our digital Jetrion 4900 press. The latter comes with a digital laser die cutting station and can print any label in any shape or size in one process. The digital press is ideally suited to make thermal printer labels of up to 50,000 per order. Any more than 50,000 labels would need the use of the MPS-350 or Edale Alpha flexographic press.

Advanced encryption keeps your data safe and secure

Advanced encryption keeps your data safe and secure