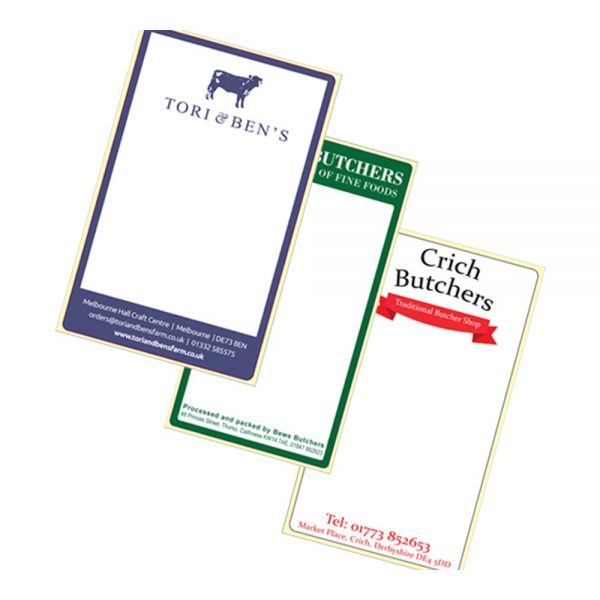

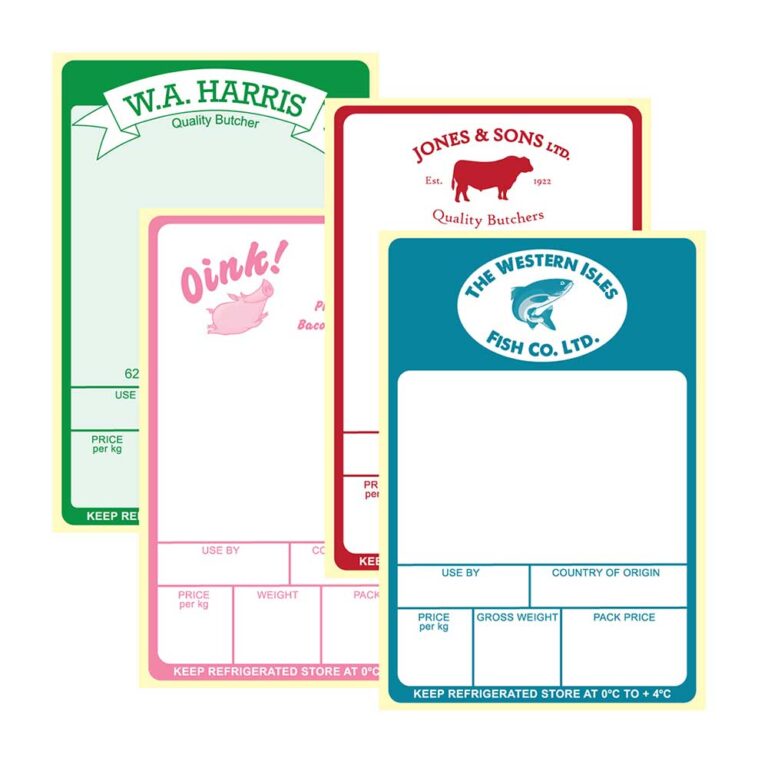

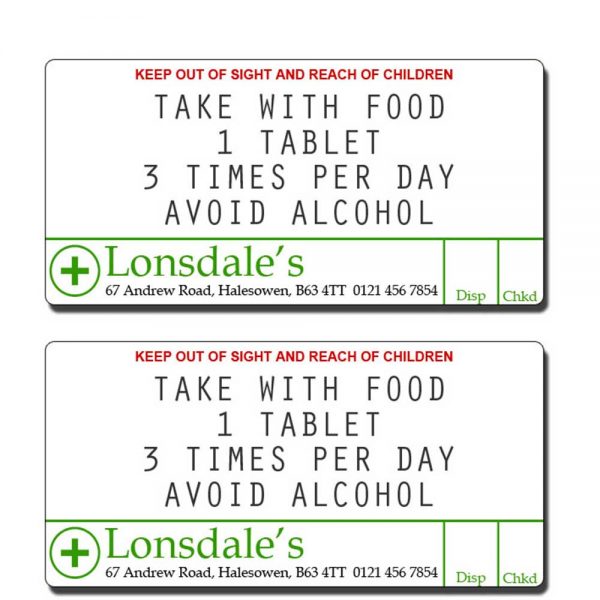

Whatever the product you have that needs to be labelled, we can make your product labels in large or small volumes, cost-effectively and to a high standard.

We have a proven track record in manufacturing product labelling solutions that sell your products, be it a simple redesign to give a new fresh look, a new product launch or a total rebrand we have the experience and expertise along with modern digital and flexo printing presses to produce labels at a competitive price.

Positive ID Labels can manufacturer product labels in small runs or large runs from 1,000 to a million labels with ease. We can manufacture your product labels using flexographic technology or digital print technology.

Why buy Product labels from Positive ID Labels

We assign and Account Manager to all our customers to ensure you get the best advice and service

We use the best materials and state-of-the-art equipment to ensure the products we make are of the highest quality.

- We are extremely competitive on price – we will try to beat any quote you have or your current supplier

- All employees at Positive ID Labels are paid at least the national living wage

- Fast turnaround and despatch for next working day delivery as standard

- UK based family run business, small enough to care but big enough to cope

We can prepare artwork for you or you can send us artwork from your graphic designer. Alternatively, if you want to prepare artwork yourself please refer to our artwork guidelines so that we can process your order quickly and accurately.

Product Labels – Materials and Adhesives

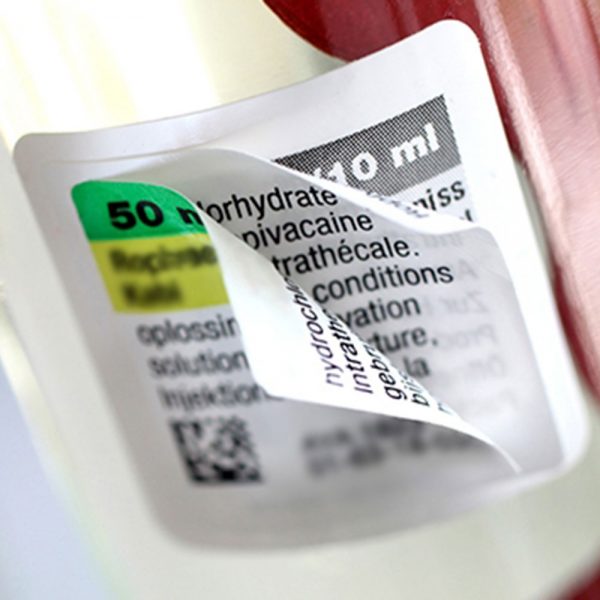

Product labels can be manufactured for any purpose and can be made on a range of materials suitable for the environment in which your product will be used. We commonly make self-adhesive labels using paper (vellum), coated papers (semi-gloss) or plastics such as polypropylene which is ideal for products requiring water resistance. We can manufacture products using specialist materials too – just call us to discuss your needs.

Adhesives come in four main ‘flavours’: Removable (or Peelable), Permanent, Freezer grade and High Tack. The first two names are self-explanatory. Freezer grade adhesive – like any adhesive – will not adhere to frost on a surface. Nor will it adhere if water is on the surface of the product being labelled. Freezer adhesive will stay adhered to your product down to a temperature of -32oC.

Removable/Peelable, Permanent and Freezer adhesives are all made using PVA glue at stronger concentrations to give more ‘grab’. PVA is environmentally friendly and biodegrades quickly. High Tack adhesive is specialised and are not suitable for foods due to the highly volatile nature of the adhesive. High Tack adhesives use gums that require organic solvents.

Flexographic Product Labels

Flexographic product labels are manufactured using flexographic printing presses. Flexographic printing presses use printing plates wrapped around a print cylinder. Once the stock material has been printed with your design, we use cutters to cut the shape of the label. The matrix around the labels is then stripped away leaving a roll of stock. This master roll of labels is then slit down into lanes and spooled onto cores with a specified number of labels or length of material, depending upon your specification.

This printing technology allows us to run our presses at high speeds up to 100 metres per minute. This means the production cost of your product labels is reduced; ideal for large order volumes.

Once we agree the artwork design with you, we will send the artwork to our plate manufacturer to supply your printing plates. If we require a special cutter, we will order that at the same time. We normally receive the tooling back within 48 hours and can start the production of your labels as soon as possible. Our normal delivery time is less than 10 working days although we aim to achieve better than that.

Digital Product Labels

For digital printed files we will use our Jetrion 4900 digital printing press. This uses UV bubble jet ink technology to make product labels at a speed of 20 metres per minute.

Our digital printing press has a laser die cutting station incorporated into the machine this means that we can print and cut your product labels in one process and finish it on the machine. We aim to deliver your digitally produced product labels in 4 working days from the agreement of artwork.

Digital printing technology means that any errors or problems with the file can be rectified on the computer. There are no physical plates or cutters involved in the process.

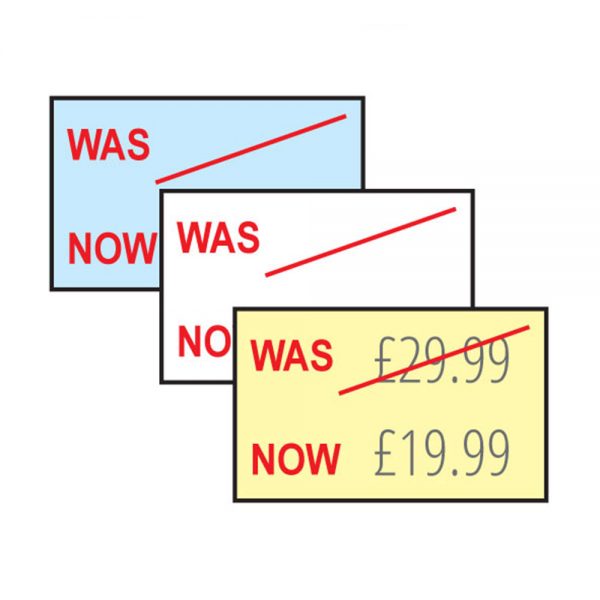

Any changes you require, special offers you might want or the addition of awards or competitions can be incorporated into your product labels quickly and easily. The shape of your label can be varied by simply redrawing the outline and can be placed back on press within 5 minutes of the change.

Advanced encryption keeps your data safe and secure

Advanced encryption keeps your data safe and secure