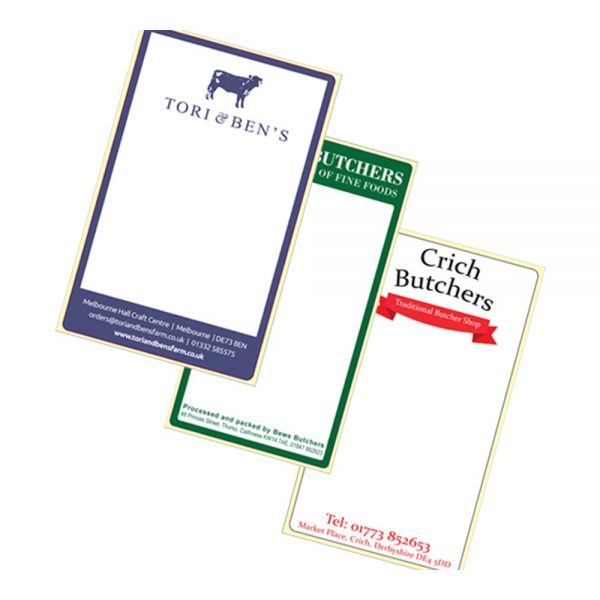

Food labels make an important contribution to the sale of your goods; they need to be eye-catching to compete with other similar products on the shelf. Luckily, our printing process combined with the great graphic design’s will have you selling your products in no time!

Food labels come in all shapes and sizes and customers need all kinds of volumes – whether it is 1 million or 1000, we can help. We use two types of printing technology for preparing your food labels. Flexographic printing for large volume orders of food labels and the like, and digital printing for smaller volume orders. Whether we make your labels flexographically or using our digital equipment, you can be assured of vibrant colours and striking impact.

Flexographically Printed Food Labels

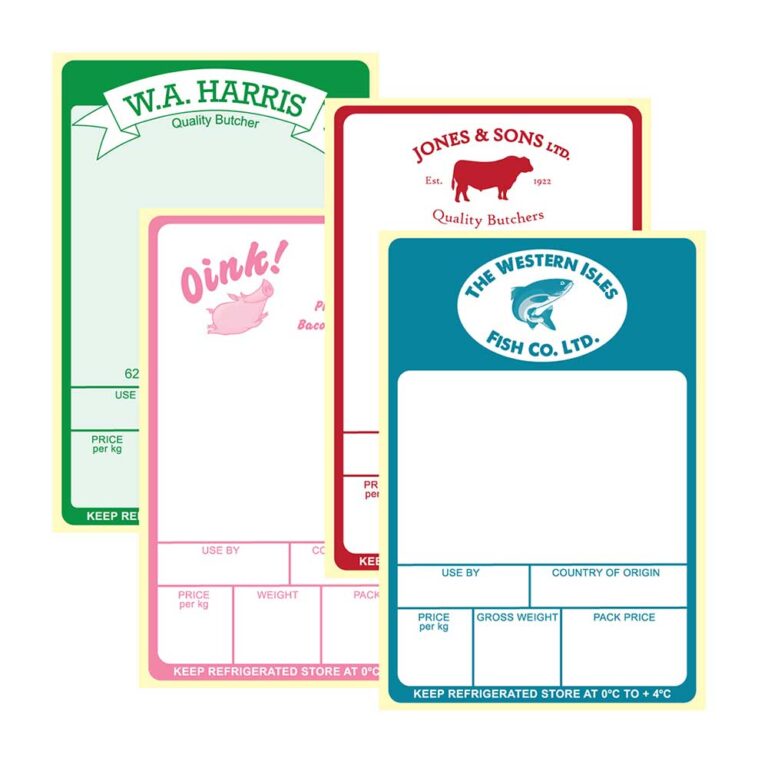

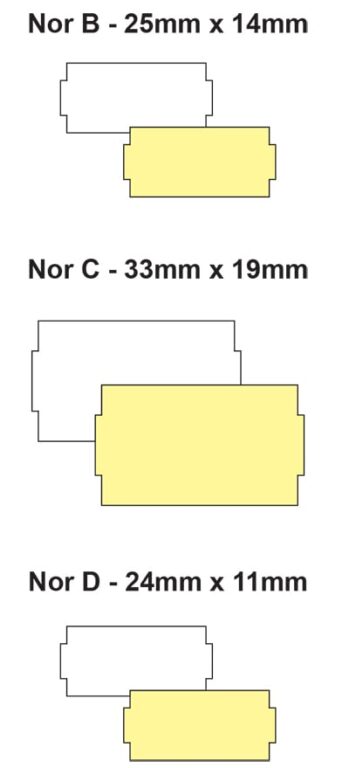

If you need lots of labels, it is more cost effective to make them flexographically. Most butchers labels and bakery labels are made in larger quantities and use flexographic printing. This method uses printing plates and rotary die cutters. The printing plates are specific to your design and we will order them once you have agreed the artwork for your label. If you have a very specific size, we will need to order the rotary cutter tool to make your labels too.

Flexographic printing is done using our MPS EB370 printing press. This is a very high-quality printing press and can run at up to 120 metres a minute. This reduces time and cost on your labels. Because we need printing plates and a cutter for your labels, there is a one-off set up charge to pay for the tooling. Plates are charged at £35 per plate and cutters vary in price from £60 to £200 depending on the complexity, size, and shape.

Digital Bakery Labels and Butchers Labels

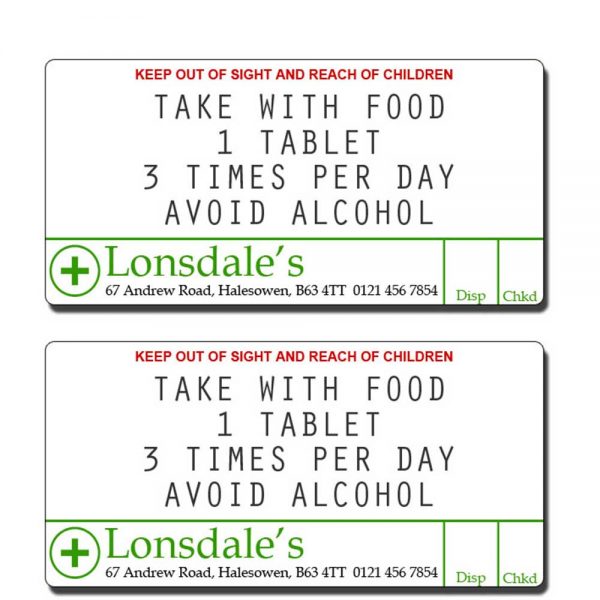

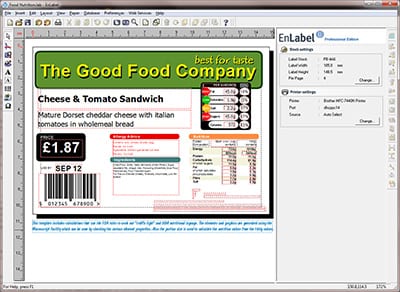

For smaller outlets, it may be cost effective to order a smaller quantity of food labels. This is particularly useful for smaller outlets or start-ups where large food label orders may not be suitable. A typical example would be sandwich labels for a start up. These can be made for use with our sandwich labelling systems.

Using our Jetrion 4900 digital press with laser die cutting station, we can make full-colour labels on a range of materials including clear or metallic polypropylene. The press uses bubble jet printing technology, similar to that of your desktop colour printer – just on an industrial scale! Printed material is then passed through a laser die cutting station that will cut your food labels to any shape that we draw – this is ideal for fitting labels to specific packaging. A well designed and professional food label will make your product ‘shout’ from the shelf and boost your sales.

From there, waste material from the master roll is removed and your labels are slit and wound onto rolls ready for delivery. The process is a single step from the stock material to the finished item.

Design for your Food or Sandwich Labels

One of the most important steps is to design a label with impact. Investing in brand and design for your product could be key to its success. You can supply artwork to us and we will convert this into production-ready files. Alternatively, you can have our in-house design team work on your product and create a label with impact. For simple designs or large orders, we may be able to provide free artwork – an offer rarely seen with our competitors. For start-up food companies needing their first order of food labels, that could be a really important saving for you.

Expertise and Knowledge

Expertise and Knowledge

Advanced encryption keeps your data safe and secure

Advanced encryption keeps your data safe and secure