Custom Printed Labels from Positive ID Labels

Buying Custom Printed Labels need not be difficult. Here at Positive ID Labels we have years of experience. We are happy to guide you through the process from start to finish.

We deal with large and small customers alike. If this is your “first rodeo”, we are here to help you through the label buying process from start to finish. We pride ourselves on service and as a new buyer, we promise you will enjoy this experience.

Step One: Custom Printed Labels Purpose

The starting point to get your order underway is to know what you are trying to achieve.

Is the product you need a standard product such as a price gun label or a thermal printer label?

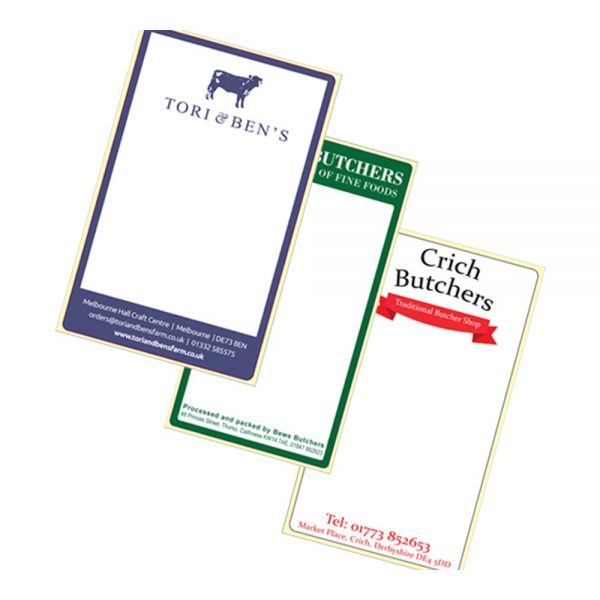

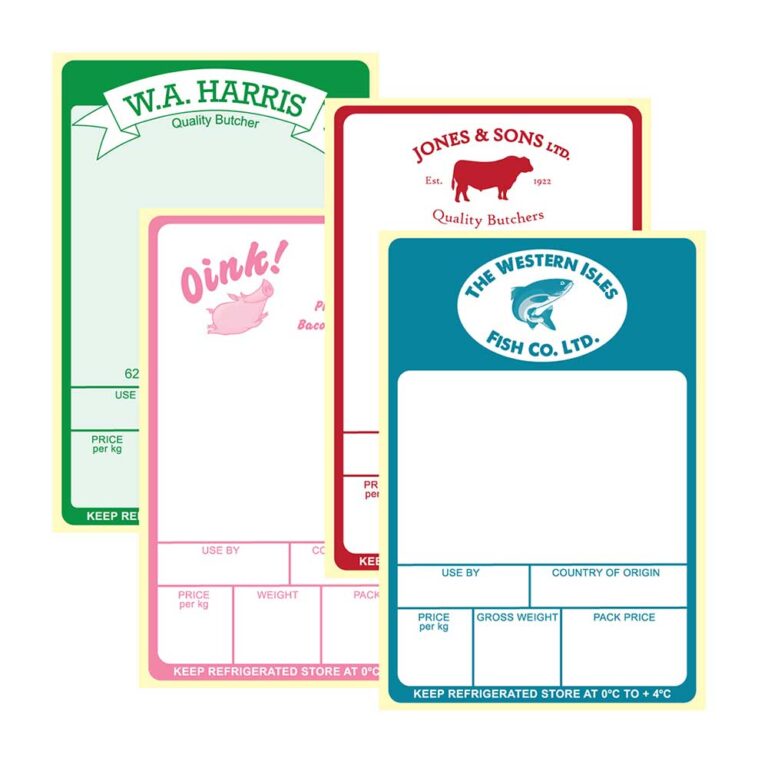

Is it a custom printed product label?

For label gun labels and thermal printer labels, life is easy and we will guide you through the process in no time. You can read about choosing different types of thermal printer labels here.

Call us now on 01332 864895 to get your order underway.

We can guide you through the whole process.

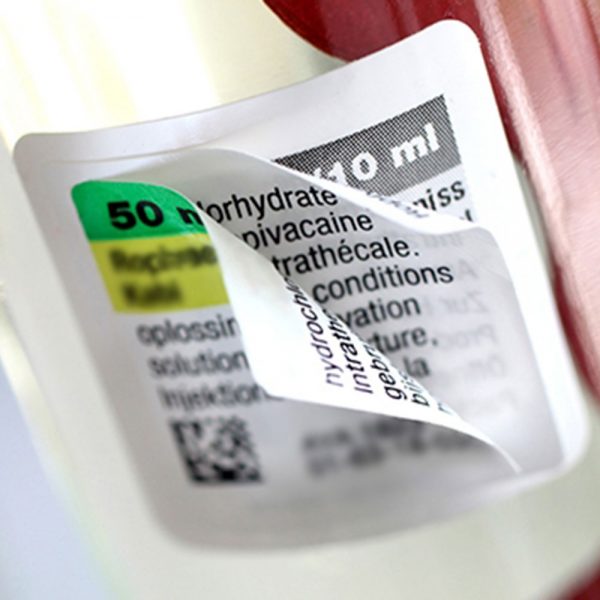

If it is a custom printed label, we will need to to know its working environment. This will help us tell you of the right material and adhesive you need for your label.

For example, if you need drinks labels, it will make sense for the label to be waterproof. It will also need a strong adhesive. If you need a label to go on a plastic pouch for some cakes you sell, a paper material with a permanent adhesive should be fine.

Once we know what you are trying to achieve and the purpose of the label, we can tell you about the material we recommend.

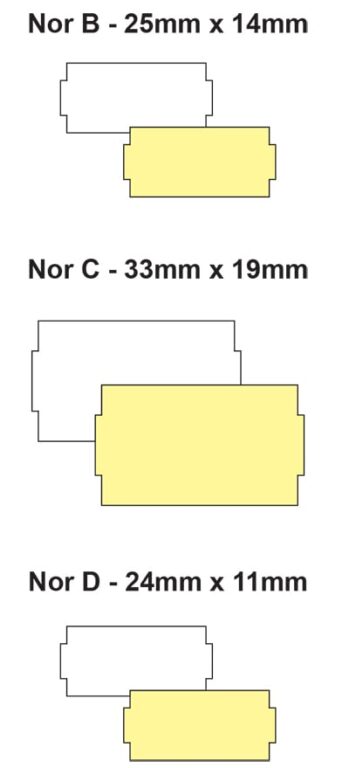

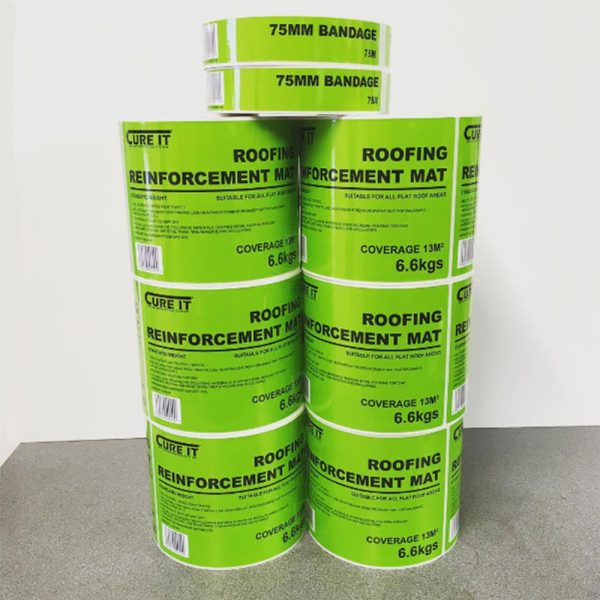

Step Two: Custom Printed Labels Sizes and Shapes

The next thing we need to know is the size and shape of the label. Your product will determine the size to an extent but we can guide you to optimise for a better price.

We always describe labels based on the width, then the length coming off the roll.

Labels are made from large rolls of material and we cut the shape using either a “rotary cutter” or a laser. The rotary cuter is a metal foil tool wrapped around a cylinder. This cylinder rolls over the surface of the material and cuts the shape of the label. Because it is a physical process, there are physical limitations but we look after that.

We also have digital laser cutting equipment. With laser label cutting, there are no limitations to the shape or size of your custom printed labels.

Step Three: Quantity and Finish of your Custom Printed Labels

Once we know the material, size and shape of your custom labels, we need to know how many you want and how you want them finishing. You have a number of choices to make at this point:

Winding

Winding is how the labels come on the roll:

- Inside wound – with the label facing inwards on the roll

- Outside wound – with the labels facing outward – i.e. you can see the labels on the roll

Orientation

Generally speaking, a label will have an obvious orientation so you would know which way to look at it. We need to know how you would like your label presented on the roll. Options are:

- Foot first

- Head first

- Left hand leading

- Right hand leading

Core size

We offer 25mm (1 inch), 38mm (11/2 inch), 44mm (13/4 inch) and 76mm (3 inch) cores. We will advise you on core size in relation to label size; long labels do not sit well on small cores.

Quantity per roll

We will supply your label order divided onto rolls with a set number of labels on each roll. Small numbers of labels on each roll will incur a small reelage surcharge.

Once we know the material, size, quantity and specification of your custom printed labels, we can give you a quotation. This will include any one-off costs we incur for tooling to do the job and any artwork charges we might need to pass on.

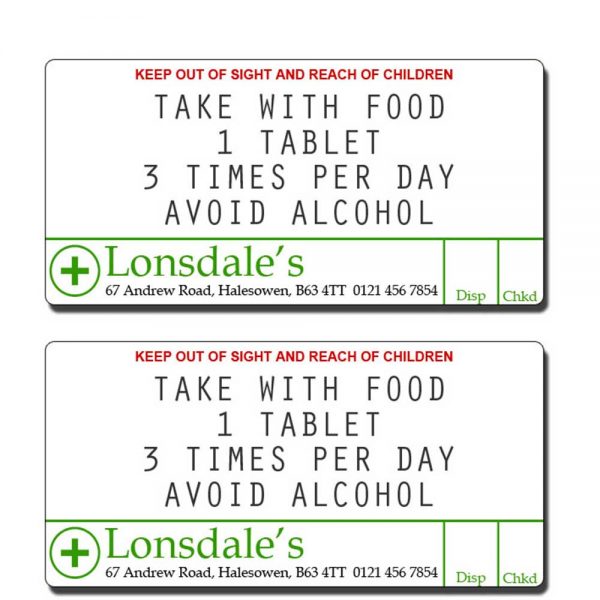

Step Four: Your Custom Printed Labels Artwork

If you accept our quotation, we can start on the detailed work in readiness for production.

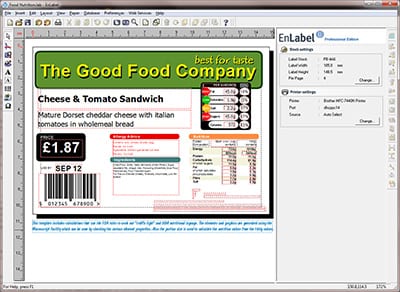

You may already have a simple design or a complex design. This should prepared to our preferred artwork standards wherever possible.

You may only have an idea of what you want or you may have a complete brand already prepared. Whichever is the case, we need to take your artwork and prepare the files for production.

Preparation is a specialised process and one we can only do in-house as the systems we use are specific to our equipment.

Once we have prepared your artwork for production, we will present you with a Design Confirmation for you to approve. This is a very important step as we will not print anything without your approval. We also measure the delivery time from the point at which you approve the designs.

The Design Confirmation will show your label at 100%, along with all the printing specification such as the print method we will employ and the finished product orientation and reelage.

Once you have approved artwork, we pass the responsibility for the job to you – i.e. we will make the product as per the proof. If there are any errors discovered after this point, we cannot accept responsibility for the errors once the product is made or other costs are incurred.

At this point, the job is passed to production and you can sit back a while whilst we get your labels made.

Step Five: Production

We will have explained to you how we will make your labels. This can be using digital printing technology or flexographic printing technology. Digital production can start quickly but the speed of production is slower. This is ideal for short runs of labels. There are no tools or printing plates required. We recommend digital printing for low volume work and flexographic printing for high volume work.

Digitally produced labels are made “inline”. This means the printer uses no specialised tools to print the label. The whole machine is specialised! Our digital printing operation includes a laser die cutting station. This means we will cut the shape of your label with a laser. The laser is programmed to cut any shape or size and there are no tooling charges for this.

Digitally produced labels do not, therefore, carry any cutter or plate charges. Digital printing speeds are slower than flexographic printing and we produce about 20 metres of labels a minute, up to 200mm wide, using this method.

Flexographically produced labels use rotary printing plates and rotary cutting tools. It is a mechanical process requiring tools specifically for each job. The number of printing plates needed will depend on your artwork. There will always be a need for a cutter but we hold over 1,000 cutter sizes and shapes to choose from. If you choose from a cutter we already have in our library, there will be no cutter charge.

Flexographic printing is ideal for mass label production. The MPS press we have can print over 100 metres of material a minute, up to 330mm wide. This means we can print for example, three 100mm wide labels at a time and then slit the master roll down to the label rolls you specified.

Step Six: Delivery and Payment

Once we have finished producing your labels, we will send them the same day for next day delivery. There is normally a £10 charge for this but larger orders may require a pallet which will be priced differently.

We convert your order to invoice on the day we dispatch it. First-time customers must pay their invoice before dispatch but once you have ordered and paid, you will be given a 30-day credit account.

It really is simple and you can rest assured, we will help you throughout the process.

Start your order now by calling 01332 864895 now!

Alternatively, fill in the form at the top right of this page and we will contact you by return.

Advanced encryption keeps your data safe and secure

Advanced encryption keeps your data safe and secure