Variable Components Need Variable Labelling

Positive ID Labels are pleased to announce an unusual variable labelling solution with a local firm, Trecarn Engineering based in Coalville, Leicestershire. Trecarn specialises in supplying equipment for use in engines and plant. This can be air ducting, heating ducts, heated hydraulic or fuel lines as the company does a lot of work for winterisation of plant.

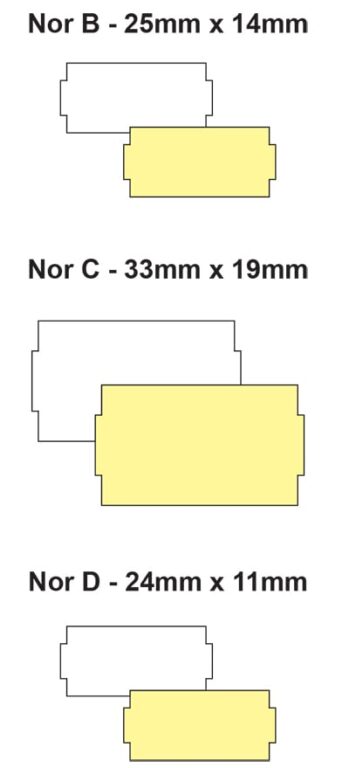

By their nature, these products vary in diameter from between 5mm to 150mm or more. The labelling solution Trecarn needed was one where they could vary the length of the label being produced to wrap around the product. For example, a 10mm heated fuel line might only need a label 50mm long. A 150mm diameter air ducting kit may need a label 600mm long to wrap around the tube.

Trecarn are a specialist manufacturer delivering products to very restrictive tolerances. This requires effective quality control. The labelling solution required needs to facilitate the use of their products. It would also be needed for replacement in the field. Engineers need to be able to identify the manufacturer and part from the label should replacements be required.

Trecarn needed a solution to identify themselves as the manufacturer with contact information for engineers in-field to be able to contact them for replacements or advice. The labels would require this information to be printed on the variable labelling solution we provided. Along with this would be part number, operative and any critical information such as tolerances and environmental condition extremes.

Variable Labelling Solution

We chose to provide a thermal transfer printer and software with blue resin ribbons in Trecarn’s corporate colours. The material provided was a specialist highly durable plastic with superb adhesion and physical durability as well as high and low-temperature tolerances. This meant the label would perform to requirements in engine bays at high temperature or when subject to arctic conditions.

The plastic material was pre-perforated lengthways at 25mm intervals. The roll provided was 100mm across and 74m long to fit within the printer.

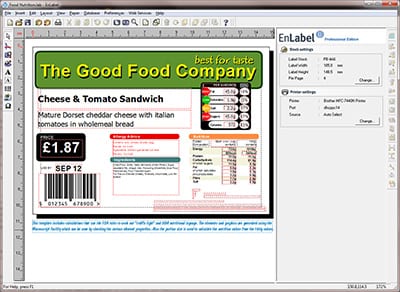

The software allows the user to choose the label length (and width within the pre-perforated widths). The user can incorporate a logo, contact information adn a plethora of other details such as the operative name, the date of production, operating variables, batch numbers and barcodes to assist with part cataloguing and production quality control.

The Label Direct software supplied with the printer has the capability of printing multiple serial numbers, operator information, batch codes and barcodes on the label. Tracking and quality control regimes can be followed easily and accurately. You can see a video relating to the printer capability here

Commenting on the order, Mark Hurst, Sales Director for Positive ID Labels said

Positive ID Labels pride themselves on establishing working solutions for their customers that are not just effective for the criteria that is specified but cost effective as well. The technical experience we have in-house enabled us to quickly identify the parameters of the problem and conclude an effective solution. We love dealing with quirky issues like these and seeing our products in place in a wide range of labelling scenarios.

For more information on Positive ID Labels label printers don’t hesitate to call us on 01332 864895 or fill in the form below:

Advanced encryption keeps your data safe and secure

Advanced encryption keeps your data safe and secure