There are two main types of thermal printing available:

- Direct Thermal Printing

- Thermal Transfer Printing

How Thermal Transfer Printing Works

Thermal printing works by heat being applied to a material (substrate) which in turn forms an image on that substrate (e.g. paper). The heat comes from a thermal print head – a device with hundreds of ceramic heating elements in a line.

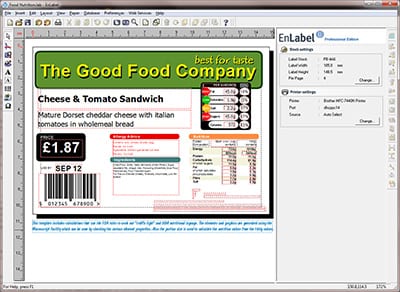

By passing a material under the print head and switching the heaters on and off an image can be formed on the material. The number of ceramic elements in a print head determines its printer resolution. The resolution determines how refined the image being printed can be. Thermal printers come in 3 common resolutions; 200dpi, 300dpi and 600dpi.

Thermal printing is not suitable for printing complex images but is excellent for printing text, characters, simple shapes such as boxes and barcodes.

Most thermal printers can print using either direct thermal printing or thermal transfer printing methods. Direct thermal printing uses no ink whereas thermal transfer uses an ‘inking’ ribbon to print.

Direct Thermal Printing

Direct thermal printing works with papers that have been treated to discolour with heat. This is achieved by coating the material with a chemical that ‘cures’ with heat. The curing changes the colour of the coating from transparent to dark brown or black. You will be familiar with this kind of material as most credit card or till receipts are printed this way.

It is possible to get plastic based direct thermal materials but these are generally at least as costly as buying plastic labels and ribbons.

Benefits of Direct Thermal Printing

- Direct thermal printing uses a specialised material which means you need no ink

- There is no need to change inking ribbons

- Ideal for short shelf life products such as food or courier applications

Drawbacks of Direct Thermal Printing

- Direct thermal printing has a limited lifespan – the printed image normally lasts only 6-12 months in good conditions

- Direct thermal printing is sensitive to temperature and other storage conditions

Poor durability in damp conditions

Direct thermal printing predominantly uses two types of material: direct thermal economy paper or direct thermal semi-gloss paper. The former is cheaper and the latter is dearer. As a consequence of using paper, direct thermal materials are not suitable for high humidity, damp or environments where condensation is an issue such as freezers.

Thermal Transfer Printing

Thermal transfer printing works in the same way as direct thermal printing except the ink comes from an ‘inking’ ribbon. Because the underlying printing process is the same (apart from the inking ribbon), most thermal printers can print both direct thermal material and by thermal transfer with ribbons.

To transfer the image, the inking ribbon passes between the print head and the material at the same speed as the material. The material can be any untreated material but the type of ribbon will need to be suitable for the material being used. Ribbons come in three main types; wax, wax/resin mix and resin. Wax is cheaper whereas resin in dearer and gives a higher quality finish.

- Papers can use wax, wax/resin or resin

- Plastics require resin ribbons to work well

- Some plastics will not work with wax or resin

Ribbons are made of a film of heat-resistant plastic with a film coating of wax, wax/resin or resin on one side. Because it is possible to print thermal transfer labels using plastic labels and resin ribbons, this makes the finished labels far more durable in more environments than paper-based materials.

Benefits of Thermal Transfer Printing

- Cheaper non-specialised materials can be used

- Durable finish good for many years in good conditions

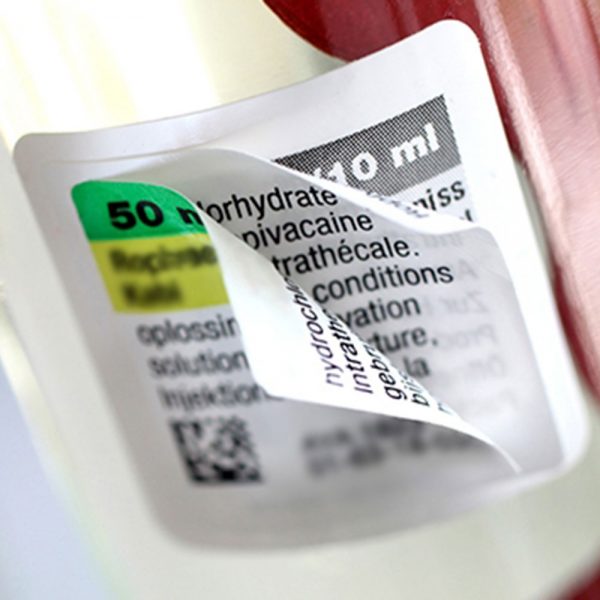

- Inert finished labels are suitable for chemical labelling or labelling subject to poor environments

- Plastic labels printed with resin are totally waterproof and resistant to many other chemicals and solvents

Drawbacks of Thermal Transfer Printing

- Additional cost of buying ribbons

- Additional fuss of installing ribbons

- Additional plastic waste created through use of ribbons

Advanced encryption keeps your data safe and secure

Advanced encryption keeps your data safe and secure